Optimizing Geomembrane Design and Operation Using the Action Leakage Rate

Author: Gary Arndt, Vikek Environmental Engineers, LLC

Geomembrane-lined lagoons present unique challenges during their design and construction as well as over the many years they are in service. This blog post aims to help wastewater lagoon operators achieve cost-effective operations in this important waste management area.

In a lagoon designed with both an upper primary and a lower secondary geomembrane, virtually all leakage through the primary layer is captured by the secondary one. Such a backup collection layer is necessary between the two geomembranes to route all leakage to a sump at the lowest point of the lagoon, where it can then be removed and discharged back into the system. However, with this configuration, we have the operational question: how much leakage is acceptable before the primary geomembrane should be repaired?

Action Leakage Rate (ALR)

Determining an acceptable leakage rate is a material aspect of the design and permitting for a double-lined lagoon. The goal of every system is to have zero leakage, but as we know all geomembrane liners ultimately leak. Therefore we need a clear and effective protocol regarding the actions to be taken at various leakage rates. Such a set of parameters is typically called the Action Leakage Rate or ALR, and its associated ALR plan usually has several levels. The framework that Vikek uses has four stages:

Action Leakage Rate Levels

| Level 1 | Leakage is at an acceptable rate, and no action is required. |

| Level 2 | Leakage is low, and no direct action is required. However, if a leakage increases to level 3 volumes, then a required plan is developed. |

| Level 3 | Leakage has increased to a level that is high, and action is required. The plan prepared at Level 2 is activated, and a prepared addendum is available if the leakage to Level 4 occurs. |

| Level 4 | The operation of the lagoon is closely monitored to ensure that the leakage pump can remove all the leakage. If pumping or gravity discharge is not keeping up with leakage, then the operation of the lagoon needs to be ceased, or an operating level that reduces leakage to Level 3. Repairs to the primary geomembrane must be made. |

Setting Fluid Levels

We treat each lagoon on a customized basis, depending on its own usually unique parameters: surface size, depth, surrounding environment, local regulations, etc. However, as a general rule, the minimum Level 4 cease-of-operation leakage that Vikek uses is 10 gallons per minute. This requires only a modest pump size that is readily available and can fit in a small diameter pipe.

High-quality guidance for ALRs and geomembrane challenges.

Setting the ALR is just one step in the design, construction, and installation of high-quality geomembrane-based wastewater lagoons. For your project of this type, it will be critical to know all of the current best practices regarding this type of facility. A highly cost-effective tactic for obtaining and implementing this knowledge is to leverage the skills of Vikek Environmental Engineers.

Why Vikek Environmental Engineers provides the foremost solutions for Wastewater Lagoons and geomembrane applications.

Our understanding of the best practices of geomembrane applications helps us quickly achieve an optimal solution regarding leakage during the transitory cleanup of landfills and other solid waste facilities.

With Vikek you will receive clear, relevant, and state-of-the-art guidance that will successfully lead you to implement best practices regarding all aspects of wastewater lagoon management. You will receive advice on how to implement solutions that leverage our decades of related experience and current industry standards, from experts that have very successfully designed and executed such techniques in Washington State, including near the Seattle area, well known for its substantial rainfall each year. See our portfolio for examples.

Project Example

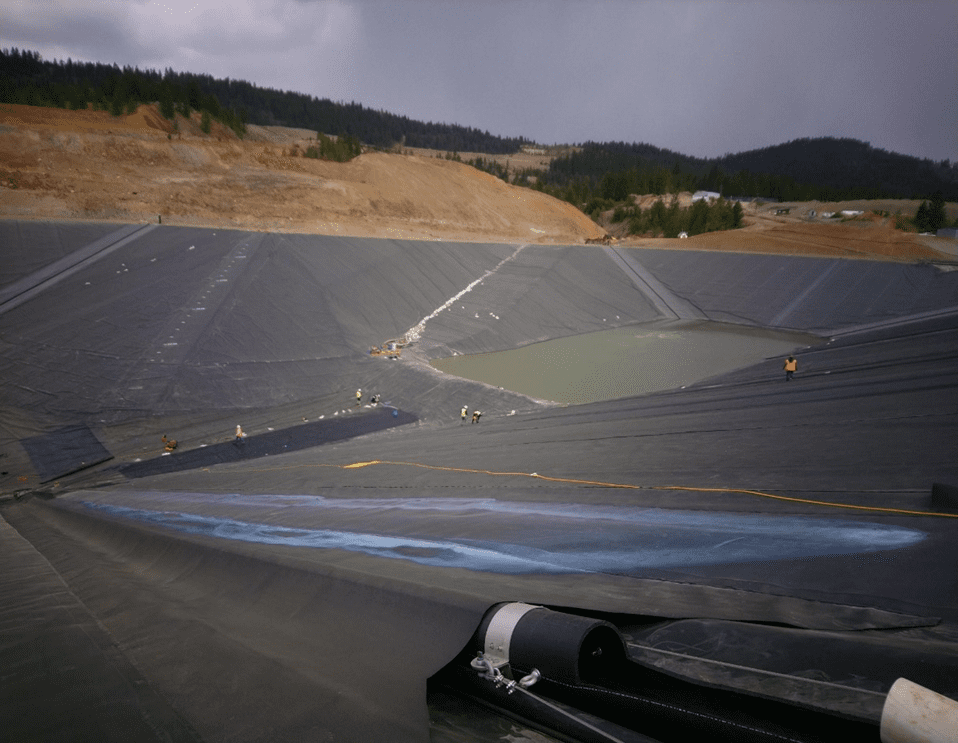

Newmont Wastewater Lagoon Liner and Floating Cover Assessment and Construction Quality Assurance Project, Ford, Washington State.

The Newmont Wastewater Ponds are double lined with a 60-mil, textured, high-density polyethylene (HDPE) geomembrane with a geonet between the geomembranes to provide leak detection. The ponds were completed in 2019 and affected water for future treatment. It has two maintenance cells in the bottom known as the west cell and the east cell, each having a storage volume of approximately 3 million gallons. See More.

Vikek personnel were chosen to develop the upcoming revised section for lagoon lining in the Washington State Department of Ecology Orange Book. Please ask for more details when you call us for a consultation.

How Vikek Environmental Engineers will help you.

Vikek Environmental Engineers is an innovator of holistic solutions for Landfill management and has helped both public and private sector organizations transition contaminated sites and landfills into sustainable and useful environments.

We develop individualized plans for the design, construction, and operation of new and existing waste management facilities that will enable your organization to transform a sub-optimal solid waste system into a cost-effective, reliable, environmentally friendly, and fully certified operation.